Soxhlet Extraction

by

NorCal Brewing Solutions

WARNING! Extraction of ANYTHING can be dangerous, lethal, or illegal. Be sure to check your local laws and ordinances.

How is Extraction Different from Distilling?

Extraction and distillation are both separation techniques (removing or concentrating a substance). However, there are key differences:

Distilling is the process of separating and purifying liquid mixtures based on variations in their volatility (boiling points). This involves the conversion of a liquid into vapor through heating and subsequent condensation (cooling) of that vapor to obtain a purified liquid.

· Distillation: Collecting the desired product through boil-off vaporization and subsequent condensation.

Extraction is the process of extracting soluble compounds from a solid material, typically by using a volatile solvent. Extraction is typically used for extracting essential oils or other organic compounds from plants.

· Extraction: Separation and collection of the desired compound from source material without boiling the compound itself.

For our purposes, we will limit our discussion to

extracting “essential oils” from plant material using a method called Soxhlet

Extraction.

What is Soxhlet Extraction?

Soxhlet extraction is a perfect method to use when the substance of interest is present in relatively small amounts and is not easily accessible for direct extraction.

Soxhlet extraction has proven itself in laboratory settings to extract essential oils from plant materials through a process known as solvent extraction. Currently, Soxhlet Extraction is gaining popularity as a method for extracting THC (tetrahydrocannabinol) from marijuana.

How does Soxhlet Extraction Work?

This is complicated to explain! Let’s start off with a word-packed introductory paragraph. If you understand it then you don’t really need to read any further! Otherwise, things will be explained step-by-step, so read on!

Soxhlet Extraction is a method of extraction that involves continuous recirculation of a low boiling point volatile liquid (solvent) heated in a chamber. Through vaporization and condensation, the solvent macerates plant material. Once the plant material is saturated, “overflow” – containing the solvent liquid and separated plant oil - drains back into the chamber and the cycle repeats. Once the process is complete, the resulting solution is processed to remove the solvent (typically through evaporation) leaving behind the extracted oil.

What Components are Used in Soxhlet Extraction?

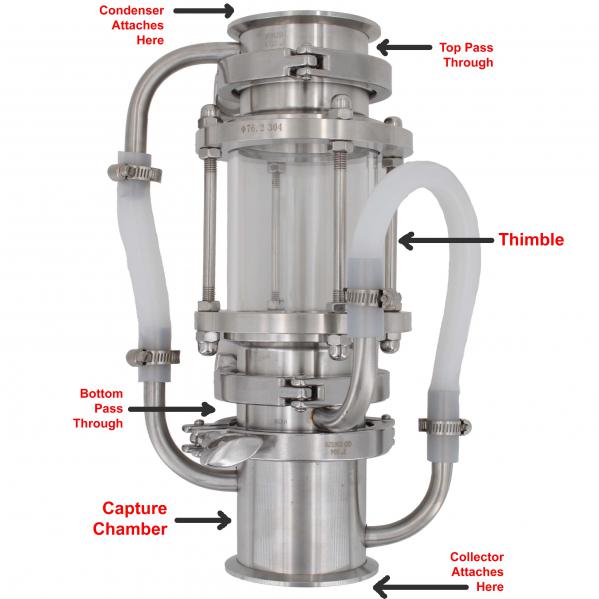

NorCal Brewing Solutions has blended standard components of Soxhlet extraction with our own engineering to produce an efficient and cost-effective system. Our components are:

· Collector: The lowest chamber of the apparatus. This is the chamber that holds the solvent and is the chamber that is heated.

· Capture Chamber: A custom-designed component that attaches to the top of the Collector and has an exit port for vapor and an entry port for extracted liquid to drip back into the Collector.

· Pass-Through: 2 identical, inter-changeable components (depending on whether they are mounted with their ports facing upward or downward):

o 1 below the Thimble, with liquid exhaust port facing upward.

o 1 above the Thimble, with vapor intake port facing downward.

· Thimble: Situated above the Capture Chamber, our Thimble consists of a Sight Glass with a welded false bottom.

· Condenser: Situated above the top Pass-Through. This device ensures water-flow temperature control cooling of the volatile vapor.

SKU# 3931 - Soxhlet Without Condenser

What are the Steps for Soxhlet Extraction?

1) Preparation of Plant Material:

a. The plant material containing the essential oil is chopped to increase the surface area available for extraction.

b. The plant material is placed inside the sight glass (Thimble), above the false bottom.

2) Assembly of Soxhlet Apparatus:

a. Assemble the Soxhlet components as shown in the picture above, keeping all clamps loose so parts can rotate without much effort.

b. The half-inch silicone tubing is installed between the upper tube (vapor exit) of the Capture Chamber and the Top Pass Through. Rotate these two components so that the exhaust port of the Capture Chamber lines up vertically with the Top Pass Through’s intake port.

c. The three-eighth-inch silicone tubing is used between the lower tube (liquid intake) of the Capture Chamber and the Bottom Pass Through. The hose needs to have the right amount of rise and bend to make sure the Thimble fills with enough liquid to macerate the plant material, but not completely fill the Thimble. Rotate the Bottom Pass through to bend the hose to the proper angle without kinking it.

d. When everything is positioned correctly, fully tighten all clamps.

e. Fill Collector with desired amount of solvent

f. Place the Soxhlet on the Collector. Attach securely using a gasket and clamp.

g. Place the Condenser on the Soxhlet. Attach securely using a gasket and clamp.

h. Attach cold water intake to bottom port of Condenser.

i. Attach warm water exit to top port of Condenser, with (optional) appropriate flow-control valve.

SKU# 3930 - Soxhlet With Condenser

3) Soxhlet Process:

a. Turn on cooling flow control through condenser.

b. Heat Chamber to desired temperature to boil (vaporize) the solvent.

c. Solvent vapor rises through exit port of Capture Chamber and enters Top Pass Through, continues into Condenser.

i. NOTE: There should be no visible “steam” exiting the Condenser if there is enough cooling flow.

d. Vapor condenses in Condenser, drips down through the Top Pass Through and into Thimble, dissolving the essential oil from the plant material.

e. Eventually the plant material becomes saturated. The concentrated solution of solvent and oil continues to collect in the Thimble until overflow occurs back into the Heat Chamber due to siphon action.

f. The cycle of vaporization, condensation, and dripping continues until the solvent runs clear through the Thimble (sight glass).

g. Turn off heat source to Collector.

h. Turn off flow source to Condenser.

i. Disassemble and clean all components.

4) Process Extract:

a. Collect the concentrated essential oil and solvent into an appropriate container. Clean the Collector.

b. Separate the solvent from the essential oil through filtration or evaporation.

Pro Tip for Separating… and Reusing… Solvent!

At the start of this write-up, we discussed the differences between Extraction and Distilling. Well… How about USING distilling to make the most out of extraction?

You may be asking… “How?”

By distilling the solvent OUT of the collected tincture and collecting the solvent to use over and over again!

The easiest, most cost-effective way to do this is through the use of two NorCal Brewing Solutions SKUs, plus a 2” Tri Clover / Tri Clamp gasket and clamp:

SKU# 2614 – Tri Clover – 3” x 2” Concentric Reducer

SKU# 3521 – Jaybird Pot Head Kit (Keg not included)

Simply remove the Soxhlet Extractor from the Collector, clamp on SKU# 2614 to reduce the 3” connection to 2”, and then clamp on SKU# 3521 to the 2” side of the reducer. Place a collection device at the end of the shotgun, and distill the solvent off the tincture!

Things to Keep in Mind:

Extraction is a sensitive process. The choice of solvent, extraction time, and temperature can impact the quality and composition of the final extract.

Regulations surrounding extraction (especially cannabinoids from marijuana) vary, so it is crucial to be aware of and comply with legal requirements.